The energy-saving single-phase oil-immersed pole-mounted transformer is a power transformer designed for distribution and power supply in areas where three-phase power is not required. These transformers are commonly used in large quantities in North and South America and Southeast Asia

Home / Products / Oil Immersed Transformer / Single-Phase Oil Immersed Transformer / Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer

About Us

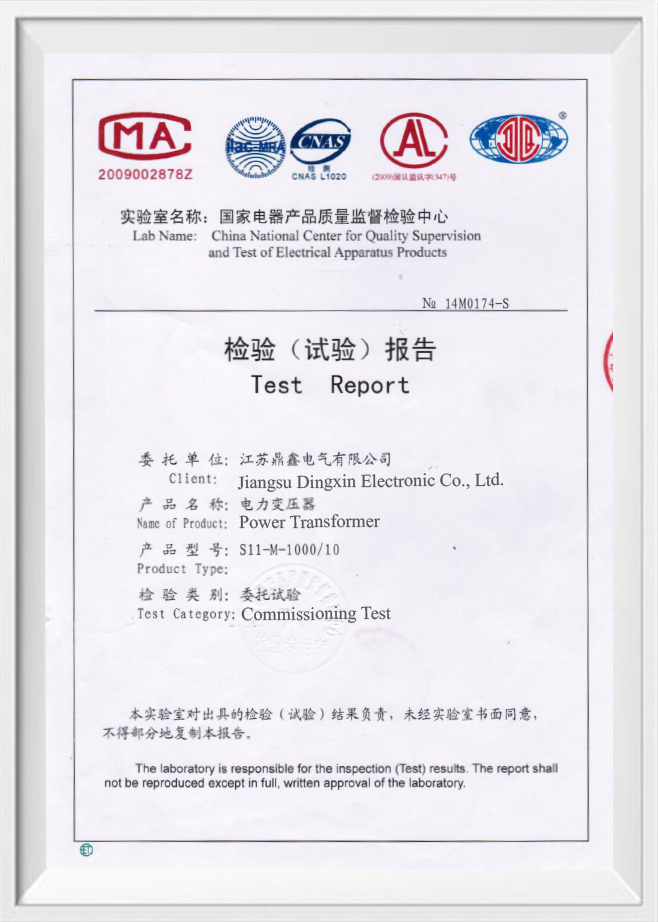

Jiangsu Dingxin Electric Co., Ltd.

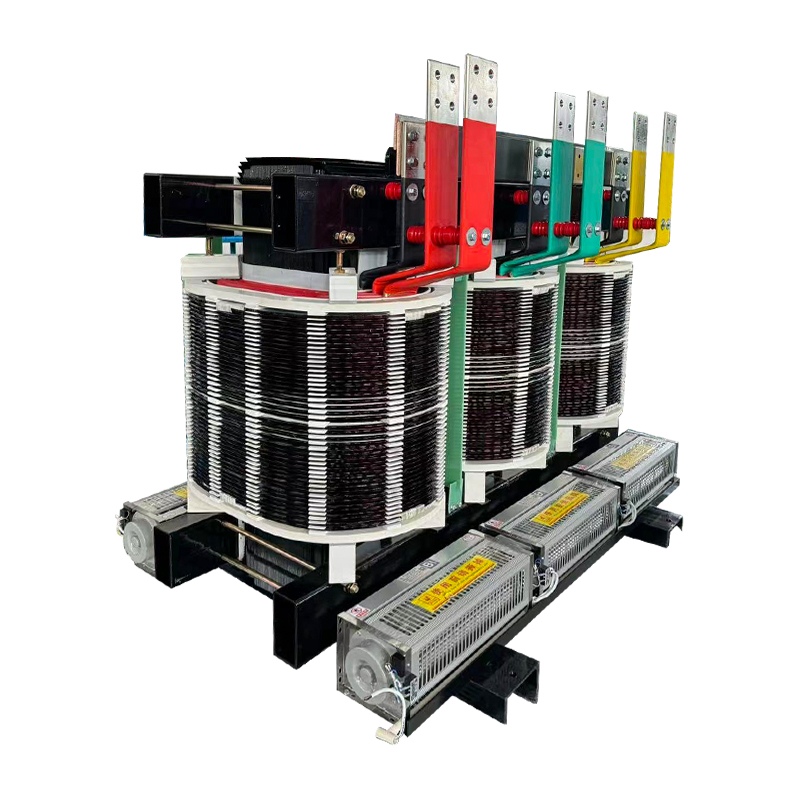

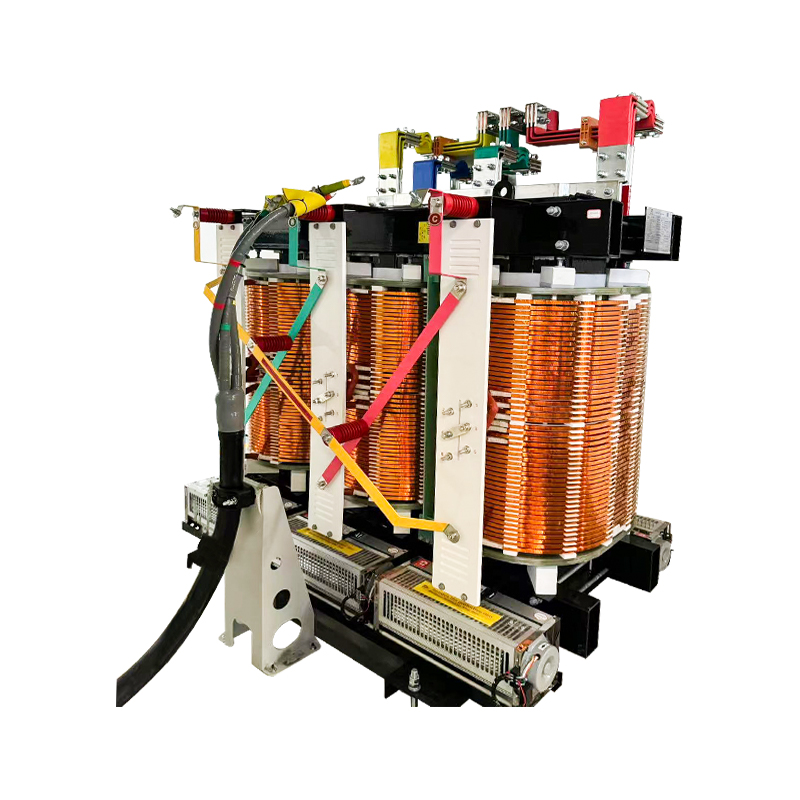

Jiangsu Dingxin Electric Co., Ltd. specialize in the production of power equipment, with an annual production capacity of 50 million KVA. It mainly produces 110KV, 220KV and 500KV ultra-high voltage transformers, various dry-type transformers, oil-immersed transformers, amorphous alloy transformers, wind and solar energy storage transformers, prefabricated substations and reactors of various specifications with voltage levels of 35KV and below. , electric furnace transformer, rectifier transformer, mining transformer, split transformer, phase shift transformer and other special transformer, custom

15KVA 13.8KV/0.4KV

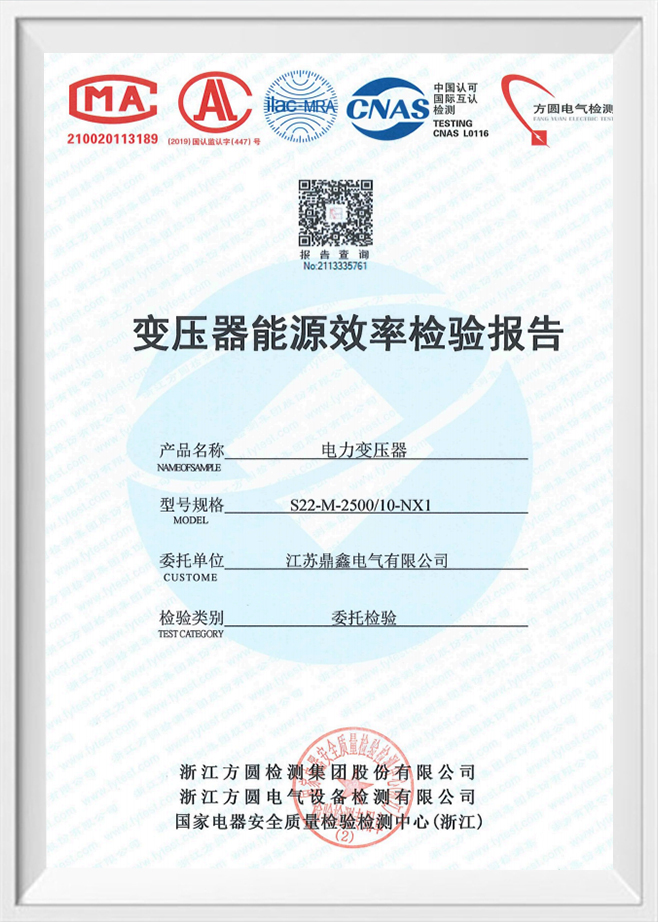

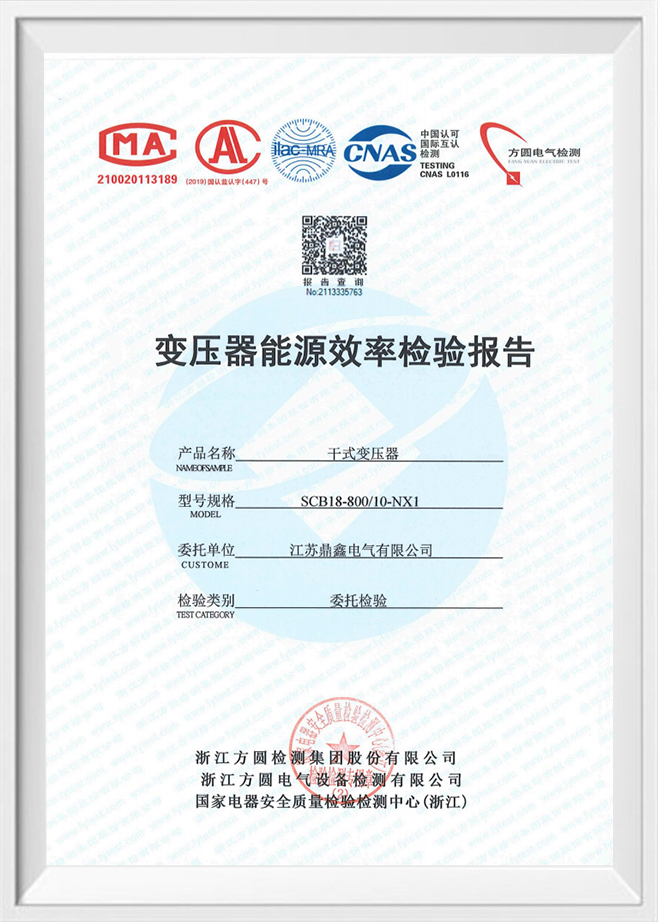

Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer. company have successively passed IS09001, ISO14001, ISO45001, ISO19011 system certification. Among the customers we cooperate with are many urban and rural power grids, as well as petrochemical, metallurgical, textile enterprises, mines, ports, residential communities, etc. We have long-term cooperation with many well-known companies, and we are also qualified suppliers for many listed companies in the electrical industry. In order to achieve high-efficiency production control, we have our own production facility and strictly adhere to procedures like screening and auditing of raw material suppliers, testing of incoming materials, and comparison of incoming materials. Additionally, each batch of products is inspected and quality-controlled in strict accordance with the supplier's indicators. As OEM15KVA 13.8KV/0.4KV

Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer Manufacturers and Factory in China, We can more readily satisfy customer demands for minimum order quantities, quality control, delivery times, etc.Product sales cover the national market and are exported to Europe, the United States, Australia, Indonesia, Russia, Africa, Vietnam and other countries.News

-

Understanding Medium vs High Voltage Inverters "Medium voltage" and "h...

READ MORE -

Understanding Cast Resin Three-Phase Dry-Type Transformers A cast resi...

READ MORE -

The pad mounted transformer is an integral part of electrical distribu...

READ MORE -

Introduction to Power Transformers and Distribution Transformers In t...

READ MORE -

Understanding switch electrical ratings Every electrical switch is spe...

READ MORE

Product Industry knowledge

What core design does Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer use to improve efficiency?

In the realm of energy distribution, the quest for efficiency is perpetual. One noteworthy stride in this pursuit is the 15KVA 13.8KV/0.4KV Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer, specifically designed to optimize performance and reduce energy wastage. At the heart of this innovation lies a meticulously crafted core design that forms the linchpin of its efficiency enhancement.

The core design of the 15KVA 13.8KV/0.4KV transformer is a testament to cutting-edge engineering principles. To comprehend its efficiency improvements, it is imperative to delve into the intricacies of the transformer's core structure. At its core (pun intended), the transformer employs advanced magnetic materials and a carefully configured geometry to minimize energy losses.

One pivotal aspect of the core design is the use of high-grade silicon steel laminations. These laminations serve a dual purpose – reducing core losses and enhancing magnetic permeability. By minimizing hysteresis and eddy current losses, the transformer can operate at higher efficiency levels, translating into energy savings for end-users.

Furthermore, the geometric arrangement of the core contributes significantly to the transformer's efficiency. The core's shape and winding arrangement are optimized through extensive computational simulations and testing. This ensures that the magnetic flux is distributed uniformly, reducing hotspots and mitigating energy dissipation in the form of heat.

The single-phase configuration of the transformer also plays a pivotal role in enhancing its efficiency. Single-phase transformers are inherently more efficient than their three-phase counterparts due to reduced copper and core losses. This makes them a preferred choice for applications where energy conservation is a top priority.

The oil-immersed nature of the transformer adds another layer of efficiency enhancement. The oil serves as a cooling and insulating medium, dissipating heat generated during operation and providing a protective barrier against environmental factors. This design choice not only enhances the transformer's lifespan but also ensures optimal performance in diverse operating conditions.

The core design of the Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer is a marvel of engineering aimed at boosting efficiency. Through the incorporation of high-quality materials, meticulous geometric optimization, and a single-phase configuration, this transformer stands as a beacon of energy-conscious design in the power distribution landscape. As the demand for sustainable energy solutions continues to rise, the innovations within transformers like these pave the way for a more efficient and eco-friendly future.

How does Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer reduce core loss and increase magnetic permeability?

In the dynamic landscape of electrical engineering, the quest for efficiency in power transformers has led to groundbreaking innovations. The Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer stands out as a shining example of such innovation, particularly in its ability to significantly reduce core loss and enhance magnetic permeability.

In the dynamic landscape of electrical engineering, the quest for efficiency in power transformers has led to groundbreaking innovations. The Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer stands out as a shining example of such innovation, particularly in its ability to significantly reduce core loss and enhance magnetic permeability.

At the heart of the transformer's efficiency lies a sophisticated core design that leverages advanced materials and precise engineering principles. Core loss reduction is achieved primarily through the strategic use of high-grade silicon steel laminations. Silicon steel, known for its excellent magnetic properties, is instrumental in minimizing both hysteresis and eddy current losses within the transformer's core.

Hysteresis losses occur due to the cyclic magnetization and demagnetization of the core material during each AC cycle. By utilizing silicon steel laminations, the Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer minimizes hysteresis losses, resulting in a more energy-efficient operation.

Eddy currents, induced by the alternating magnetic field, can lead to significant power losses in the form of heat. The transformer's core design mitigates these losses by employing laminations with insulated layers, which disrupt the paths of the eddy currents and reduce their impact on overall efficiency.

Furthermore, the geometric arrangement of the laminations plays a crucial role in enhancing magnetic permeability. Magnetic permeability is a measure of a material's ability to conduct magnetic flux, and it directly influences the transformer's overall efficiency. The careful design and layout of the laminations ensure a uniform distribution of magnetic flux, minimizing losses and maximizing the transformer's magnetic permeability.

Additionally, the transformer's single-phase configuration contributes to the reduction of core losses. Single-phase transformers inherently have lower core losses compared to their three-phase counterparts, making them a preferred choice for applications where efficiency is paramount.

The oil-immersed feature of the transformer provides an added dimension to the efficiency equation. The oil serves as a coolant, dissipating heat generated during operation and maintaining optimal operating temperatures for the core. This not only reduces core losses but also extends the transformer's lifespan.

The Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer achieves remarkable efficiency improvements through a combination of advanced materials, meticulous geometric design, and a single-phase configuration. By reducing core losses and enhancing magnetic permeability, this transformer stands as a testament to the continuous pursuit of excellence in the field of electrical engineering, offering a glimpse into the future of sustainable and efficient power distribution.

English

English русский

русский Español

Español