Home / Products / Power Transformer / 110KV-220KAV Power Transformer / 100mva 220kv Low Loss Power Transformer

-

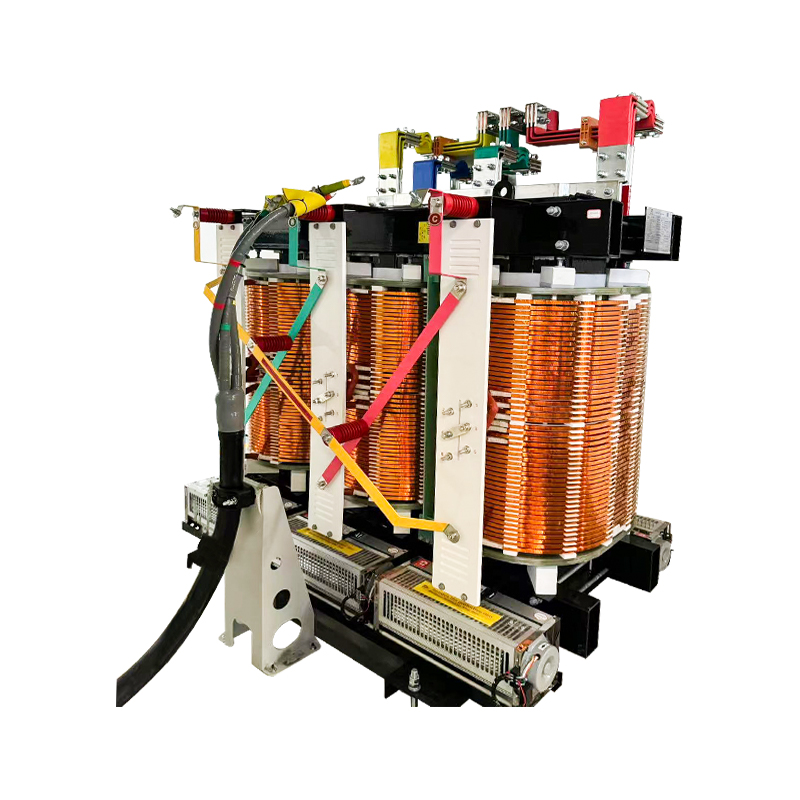

100MVA 220kV low loss power transformer is a special type of power transformer used in power transmission and distribution systems to step up or step down the voltage as needed. These transformers include safety features such as overcurrent protection, overtemperature protection and pressure relief devices to ensure safe and reliable operation.

-

About Us

Jiangsu Dingxin Electric Co., Ltd.

Jiangsu Dingxin Electric Co., Ltd. specialize in the production of power equipment, with an annual production capacity of 50 million KVA. It mainly produces 110KV, 220KV and 500KV ultra-high voltage transformers, various dry-type transformers, oil-immersed transformers, amorphous alloy transformers, wind and solar energy storage transformers, prefabricated substations and reactors of various specifications with voltage levels of 35KV and below. , electric furnace transformer, rectifier transformer, mining transformer, split transformer, phase shift transformer and other special transformer, custom 100mva 220kv Low Loss Power Transformer. company have successively passed IS09001, ISO14001, ISO45001, ISO19011 system certification. Among the customers we cooperate with are many urban and rural power grids, as well as petrochemical, metallurgical, textile enterprises, mines, ports, residential communities, etc. We have long-term cooperation with many well-known companies, and we are also qualified suppliers for many listed companies in the electrical industry. In order to achieve high-efficiency production control, we have our own production facility and strictly adhere to procedures like screening and auditing of raw material suppliers, testing of incoming materials, and comparison of incoming materials. Additionally, each batch of products is inspected and quality-controlled in strict accordance with the supplier's indicators. As OEM 100mva 220kv Low Loss Power Transformer Manufacturers and Factory in China, We can more readily satisfy customer demands for minimum order quantities, quality control, delivery times, etc.Product sales cover the national market and are exported to Europe, the United States, Australia, Indonesia, Russia, Africa, Vietnam and other countries.

News

-

Understanding Cast Resin Three-Phase Dry-Type Transformers A cast resi...

READ MORE -

The pad mounted transformer is an integral part of electrical distribu...

READ MORE -

Introduction to Power Transformers and Distribution Transformers In t...

READ MORE -

Understanding switch electrical ratings Every electrical switch is spe...

READ MORE -

Short answer — it depends on the standard and the context Most interna...

READ MORE

Product Industry knowledge

What are the specific benefits of the high voltage working capability of the 100mva 220kv Low Loss Power Transformer?

The 100MVA 220kV Low Loss Power Transformer stands out as a technological marvel, and its high voltage working capability is a key feature that brings a multitude of benefits to power transmission and distribution systems. Let's delve into the specific advantages that arise from the transformer's ability to handle 220kV.

Efficient Long-Distance Power Transmission:

The high voltage working capability of 220kV in the transformer is instrumental in efficient long-distance power transmission. According to the laws of electrical transmission, power losses are inversely proportional to voltage and directly proportional to current. By operating at 220kV, the transformer allows for the transmission of large quantities of power with reduced current, minimizing resistive losses in the transmission lines. This translates into efficient power transfer over extended distances.

Grid Integration and Connectivity:

The 100MVA 220kV Low Loss Power Transformer plays a crucial role in grid integration and connectivity. High voltage capabilities enable the seamless connection of power generation sources, often located in remote areas, to the main power grid. This integration enhances the overall reliability and resilience of the grid, ensuring a stable power supply even when faced with variations in demand or unforeseen disruptions.

Support for Renewable Energy Integration:

Renewable energy sources, such as wind and solar, are often situated in regions with abundant natural resources. The high voltage working capability of the transformer facilitates the efficient integration of renewable energy into the power grid. By transmitting power over longer distances with reduced losses, the transformer supports the incorporation of clean and sustainable energy sources, contributing to a greener and more environmentally friendly energy mix.

Reduction in Energy Losses:

Operating at 220kV, the transformer substantially reduces energy losses in the power transmission process. Lower losses mean that a higher proportion of the generated power reaches its destination, minimizing wasted electricity and enhancing overall energy efficiency. This reduction in energy losses aligns with global efforts to create more sustainable and environmentally conscious power distribution networks.

Enhanced System Reliability:

The high voltage working capability also enhances the reliability of the power system. By reducing resistive losses and optimizing power transmission efficiency, the transformer contributes to the stability of the electrical grid. This reliability is critical for meeting the increasing demands of modern societies and industries, where uninterrupted power supply is essential.

Smart Grid Readiness:

The 100MVA 220kV Low Loss Power Transformer is well-positioned for integration into smart grids. The high voltage capability aligns with the requirements of modern grid systems, which utilize advanced communication and control technologies. Smart grids optimize power distribution, monitor grid conditions in real-time, and enhance overall system efficiency, making the transformer an integral component of future-ready power infrastructure.

Industry Recognition and Standards Compliance:

Transformers with high voltage capabilities, such as the 100MVA 220kV Low Loss Power Transformer, comply with stringent industry standards. These standards, often set by organizations like the International Electrotechnical Commission (IEC) or the Institute of Electrical and Electronics Engineers (IEEE), ensure that the transformer meets established criteria for safety, performance, and efficiency. The industry's acknowledgment of these standards further reinforces the transformer's credibility and reliability.

The high voltage working capability of the 100MVA 220kV Low Loss Power Transformer opens a realm of possibilities for the power industry. From efficient long-distance transmission to seamless grid integration of renewable energy, the benefits are vast and aligned with the global push towards sustainable and resilient energy solutions. As technology continues to advance, transformers with high voltage capabilities will remain at the forefront of shaping the future of power transmission.

What advanced core materials are used in 100mva 220kv Low Loss Power Transformer?

The 100MVA 220kV Low Loss Power Transformer stands as a beacon of innovation in the power transmission landscape, and a significant contributor to its high efficiency and low losses lies in the advanced core materials employed in its construction. Let's delve into the sophisticated materials that form the core of this transformer, shedding light on the technological advancements that make it a standout in the field.

Silicon Steel:

At the heart of the 100MVA 220kV Low Loss Power Transformer is the use of high-grade silicon steel in its core. Silicon steel, also known as electrical steel or lamination steel, is a specialized steel alloy designed for its magnetic properties. The addition of silicon in the steel composition significantly reduces core losses attributed to hysteresis and eddy currents. This improvement in magnetic characteristics enhances the transformer's overall efficiency, making it an ideal choice for applications demanding low losses.

Amorphous Alloy:

Another cutting-edge material making waves in transformer technology is amorphous alloy. In some instances, the core of the 100MVA 220kV Low Loss Power Transformer may incorporate amorphous metal materials. Amorphous alloys exhibit unique atomic structures, lacking the crystalline order found in traditional metals. This amorphous structure dramatically reduces core losses, particularly eddy current losses, leading to even greater efficiency in power transmission.

Hybrid Core Designs:

In pursuit of optimizing performance, manufacturers may employ hybrid core designs that combine both silicon steel and amorphous alloy materials. This approach capitalizes on the strengths of each material, aiming to strike a balance between cost-effectiveness and maximum energy efficiency. Hybrid cores in transformers have demonstrated superior performance, showcasing the industry's commitment to innovation and continuous improvement.

Advanced Winding Configurations:

Beyond the core materials themselves, the 100MVA 220kV Low Loss Power Transformer leverages advanced winding configurations. The winding design plays a critical role in minimizing losses and optimizing magnetic flux within the transformer. By employing precision-engineered winding techniques, the transformer achieves enhanced performance, ensuring that the magnetic field generated within the core is utilized with maximum efficiency.

International Standards and Quality Assurance:

The incorporation of these advanced core materials aligns with international standards set by organizations like the International Electrotechnical Commission (IEC) or the Institute of Electrical and Electronics Engineers (IEEE). These standards establish benchmarks for the efficiency, reliability, and safety of power transformers, ensuring that transformers with advanced core materials meet rigorous quality assurance criteria.

Technological Validation and Industry Trends:

The use of advanced core materials in transformers is not merely theoretical; it has been extensively validated through testing and real-world applications. The industry's adoption of these materials reflects a broader trend towards pushing the boundaries of traditional transformer technology to achieve unprecedented levels of efficiency and performance.

The 100MVA 220kV Low Loss Power Transformer's advanced core materials showcase the transformative potential of materials science in the power industry. Silicon steel, amorphous alloys, and innovative winding configurations collectively contribute to reducing losses, enhancing efficiency, and positioning the transformer at the forefront of modern power transmission technology. As the industry continues to evolve, these advanced core materials will likely play a pivotal role in shaping the next generation of highly efficient and environmentally conscious transformers.

English

English русский

русский Español

Español