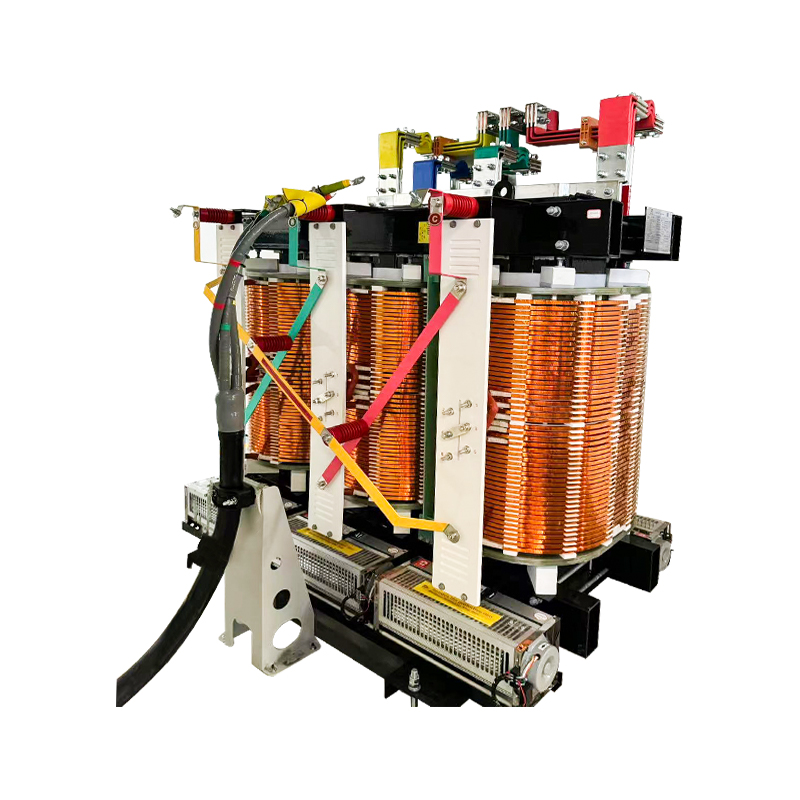

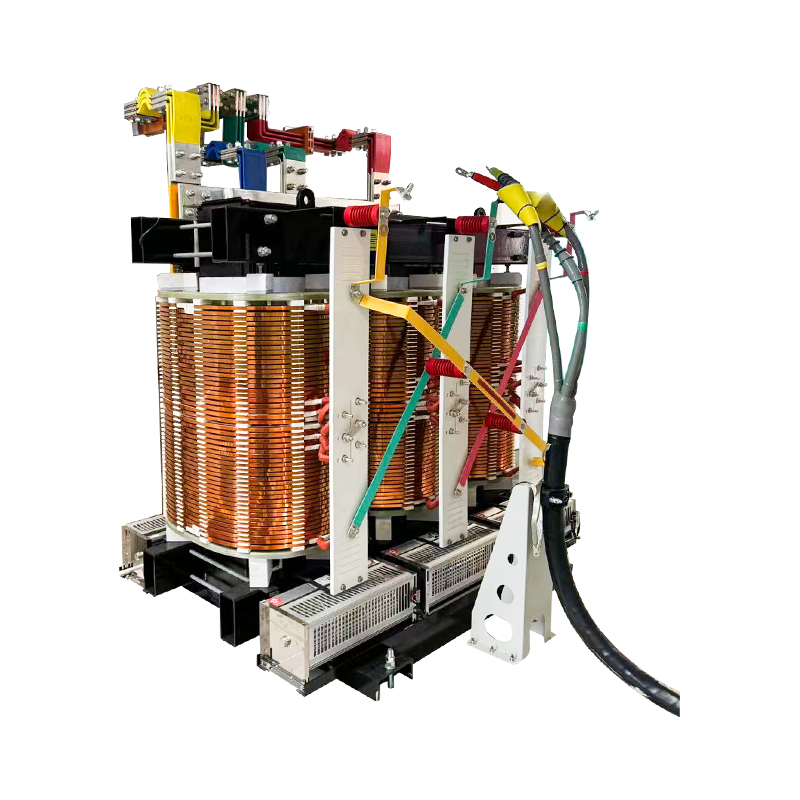

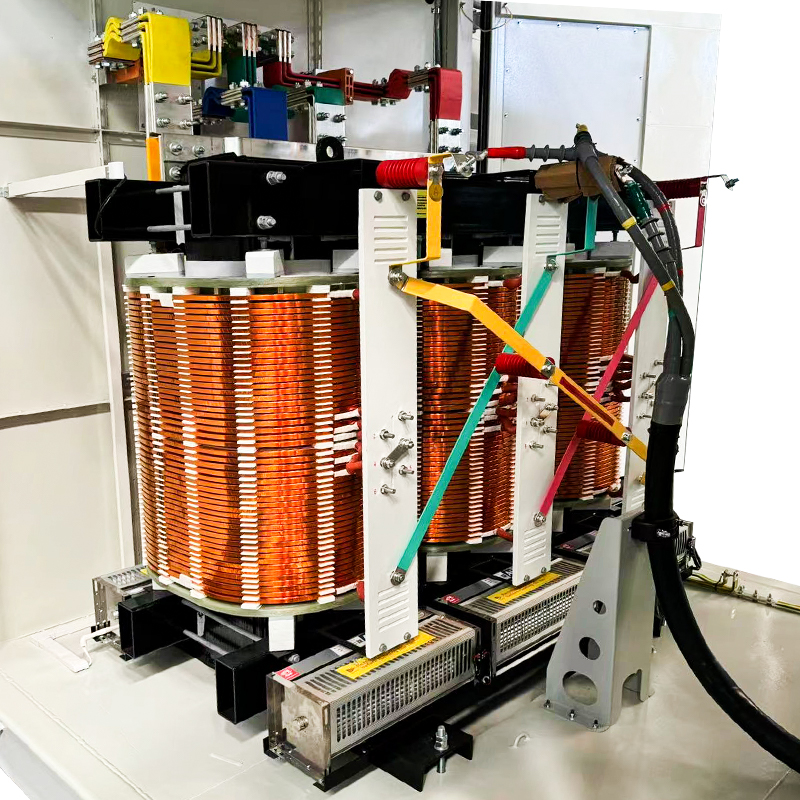

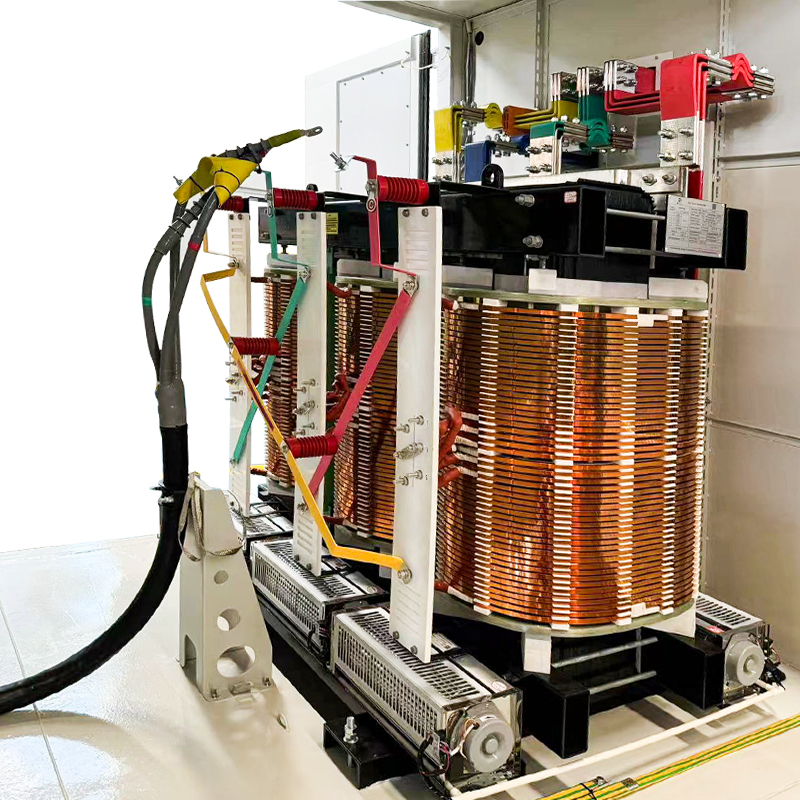

Non-encapsulated insulated dry-type transformers have the characteristics of high reliability, energy saving and environmental protection, and good heat dissipation performance, and are suitable for use in heavy-load applications. The insulation material is polymer-based and complies with the latest international standards. They are also very durable.

Home / Products / Dry Type Transformer / Insulated Energy-Saving And Environmentally Friendly Dry Type Transformer / 800KVA 10KV Non-Encapsulated Insulated Dry-Type Transformer

About Us

Jiangsu Dingxin Electric Co., Ltd.

Jiangsu Dingxin Electric Co., Ltd. specialize in the production of power equipment, with an annual production capacity of 50 million KVA. It mainly produces 110KV, 220KV and 500KV ultra-high voltage transformers, various dry-type transformers, oil-immersed transformers, amorphous alloy transformers, wind and solar energy storage transformers, prefabricated substations and reactors of various specifications with voltage levels of 35KV and below. , electric furnace transformer, rectifier transformer, mining transformer, split transformer, phase shift transformer and other special transformer, custom

800KVA 10KV

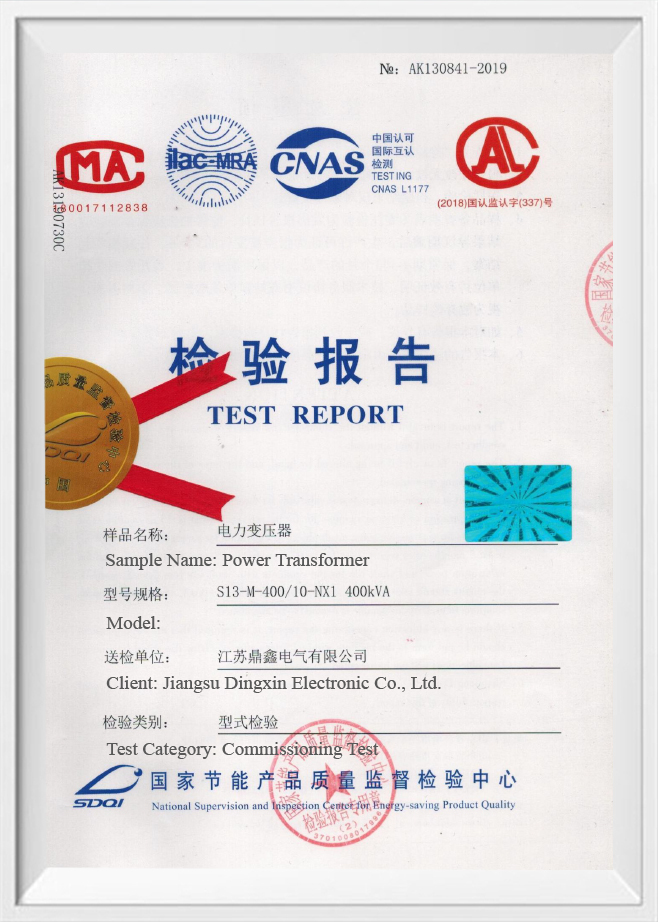

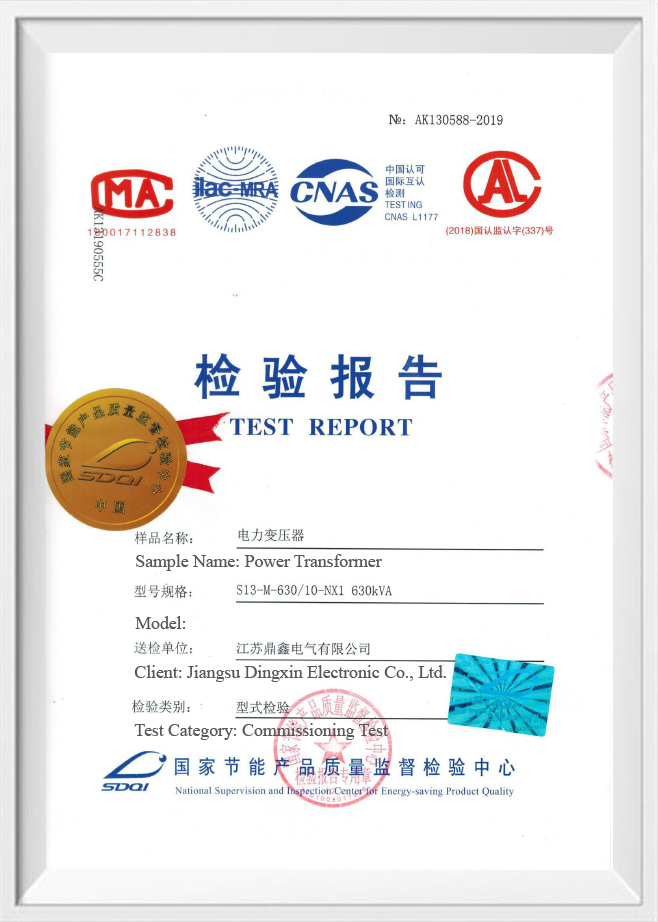

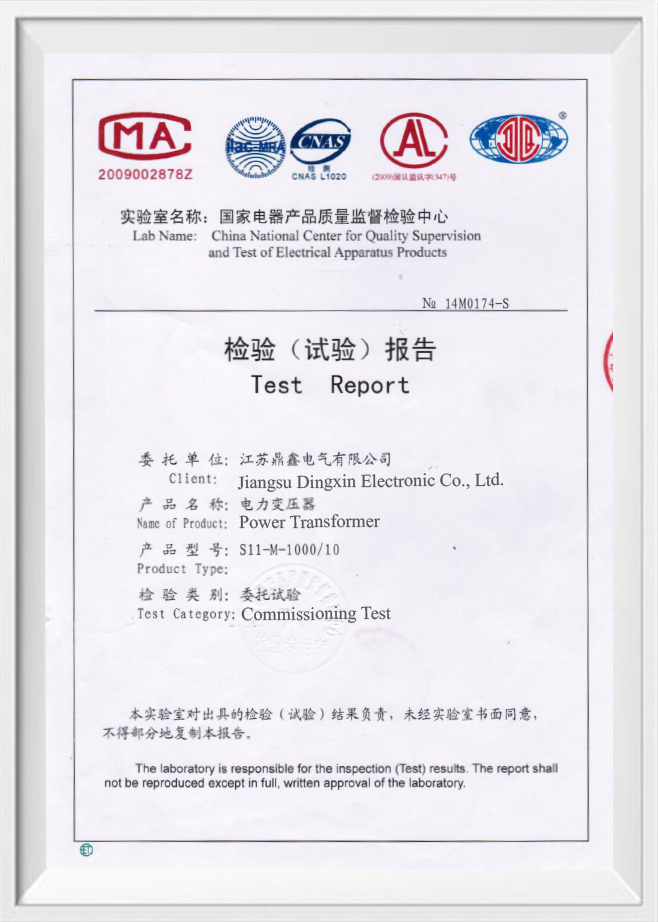

800KVA 10KV Non-Encapsulated Insulated Dry-Type Transformer. company have successively passed IS09001, ISO14001, ISO45001, ISO19011 system certification. Among the customers we cooperate with are many urban and rural power grids, as well as petrochemical, metallurgical, textile enterprises, mines, ports, residential communities, etc. We have long-term cooperation with many well-known companies, and we are also qualified suppliers for many listed companies in the electrical industry. In order to achieve high-efficiency production control, we have our own production facility and strictly adhere to procedures like screening and auditing of raw material suppliers, testing of incoming materials, and comparison of incoming materials. Additionally, each batch of products is inspected and quality-controlled in strict accordance with the supplier's indicators. As OEM800KVA 10KV

800KVA 10KV Non-Encapsulated Insulated Dry-Type Transformer Manufacturers and Factory in China, We can more readily satisfy customer demands for minimum order quantities, quality control, delivery times, etc.Product sales cover the national market and are exported to Europe, the United States, Australia, Indonesia, Russia, Africa, Vietnam and other countries.News

-

Understanding Cast Resin Three-Phase Dry-Type Transformers A cast resi...

READ MORE -

The pad mounted transformer is an integral part of electrical distribu...

READ MORE -

Introduction to Power Transformers and Distribution Transformers In t...

READ MORE -

Understanding switch electrical ratings Every electrical switch is spe...

READ MORE -

Short answer — it depends on the standard and the context Most interna...

READ MORE

Product Industry knowledge

What type of insulation material does the 800KVA 10KV Non-Encapsulated Insulated Dry-Type Transformer use?

The 800KVA 10KV Non-Encapsulated Insulated Dry-Type Transformer stands as a testament to modern engineering ingenuity. As technology advances, the quest for safer, more efficient, and environmentally conscious solutions has led to the development of transformers that eschew traditional liquid-filled designs. A key element in these transformers is the insulation material that safeguards the crucial winding components.

The 800KVA 10KV Non-Encapsulated Insulated Dry-Type Transformer stands as a testament to modern engineering ingenuity. As technology advances, the quest for safer, more efficient, and environmentally conscious solutions has led to the development of transformers that eschew traditional liquid-filled designs. A key element in these transformers is the insulation material that safeguards the crucial winding components.

Insulation Unveiled: The Heart of Transformer Efficiency

The insulation material in the 800KVA 10KV Non-Encapsulated Insulated Dry-Type Transformer is a critical component ensuring the reliability and performance of the transformer. In this sophisticated piece of electrical equipment, epoxy resin is often the insulation material of choice.

Epoxy Resin: A High-Performance Insulator

Epoxy resin is a thermosetting polymer that possesses exceptional electrical and thermal insulation properties. In the context of transformers, it is favored for its ability to withstand high temperatures, resist electrical breakdown, and provide robust protection to the winding components. The application of epoxy resin insulation ensures that the transformer can operate efficiently even in demanding conditions.

Temperature Stability: A Crucial Consideration

Transformers, especially those with higher power ratings like the 800KVA 10KV variant, generate considerable heat during operation. Epoxy resin excels in maintaining its structural integrity and insulating properties across a wide range of temperatures. This stability is crucial for preventing insulation breakdown and ensuring the long-term reliability of the transformer.

Environmental and Safety Advantages

The choice of epoxy resin aligns with the broader industry trend toward environmentally friendly and safer transformer technologies. Unlike traditional oil-filled transformers, the dry-type transformer with epoxy resin insulation eliminates the risk of oil leaks or spills, contributing to a cleaner and safer operating environment.

Meeting Industry Standards

The selection of insulation material is not arbitrary but is governed by stringent industry standards and regulations. Epoxy resin is a well-established and widely accepted insulation material in the transformer manufacturing industry. Its use in the 800KVA 10KV Non-Encapsulated Insulated Dry-Type Transformer reflects a commitment to meeting or exceeding these industry standards.

In unraveling the mystery behind the insulation material of the 800KVA 10KV Non-Encapsulated Insulated Dry-Type Transformer, we discover the pivotal role played by epoxy resin. This high-performance insulation material ensures not only the efficiency and reliability of the transformer but also aligns with the industry's drive toward safer and more environmentally conscious electrical solutions. As transformers continue to evolve, the choice of insulation material becomes a key factor in shaping the future of electrical power distribution.

Why is Non-Encapsulated Insulated Dry-Type Transformer considered more environmentally friendly?

In the ever-evolving landscape of electrical transformers, the Non-Encapsulated Insulated Dry-Type Transformer emerges as a herald of environmental consciousness. This transformative technology not only enhances electrical efficiency but also significantly reduces its ecological footprint. Delving into the core attributes of this innovation sheds light on why it is considered more environmentally friendly than traditional counterparts.

Eliminating Environmental Hazards: Liquid-Free Design

Unlike its oil-filled counterparts, the Non-Encapsulated Insulated Dry-Type Transformer operates without the use of liquid coolants. The absence of oil mitigates the risk of leaks or spills, a common concern associated with liquid-filled transformers. This liquid-free design not only ensures a cleaner working environment but also eliminates the potential for soil or water contamination, aligning with contemporary environmental standards.

Reducing Fire Hazards: A Safer Operating Environment

Fire hazards have long been associated with oil-filled transformers due to the combustible nature of the insulating oil. The Non-Encapsulated Insulated Dry-Type Transformer, being devoid of liquid coolant, significantly reduces the risk of fire incidents. This inherent safety feature not only safeguards the transformer itself but also enhances overall workplace safety, making it an appealing choice for indoor applications.

Simplified Maintenance: A Green Approach

Maintenance practices play a crucial role in the environmental impact of electrical infrastructure. Non-Encapsulated Insulated Dry-Type Transformers, by design, require less maintenance compared to their liquid-filled counterparts. The absence of liquid coolants translates to fewer monitoring and testing procedures, reducing the demand for resources and minimizing the environmental footprint associated with routine maintenance.

Meeting Green Building Standards: A Sustainable Choice

As the world shifts towards sustainable practices, the construction industry, in particular, is placing increasing emphasis on green building standards. Non-Encapsulated Insulated Dry-Type Transformers align seamlessly with these standards, offering a cleaner and safer alternative for powering buildings. The elimination of oil-related hazards contributes to achieving environmentally responsible certifications, making it a preferred choice in modern construction projects.

The Non-Encapsulated Insulated Dry-Type Transformer stands as a beacon of eco-friendly innovation in the realm of electrical transformers. Its liquid-free design, reduced fire hazards, simplified maintenance, and alignment with green building standards collectively position it as a sustainable choice for modern power distribution. As industries worldwide continue to prioritize environmental responsibility, the adoption of Non-Encapsulated Insulated Dry-Type Transformers represents a significant stride towards greener and cleaner electrical infrastructure.

English

English русский

русский Español

Español