Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer

15KVA 13.8KV/0.4KV

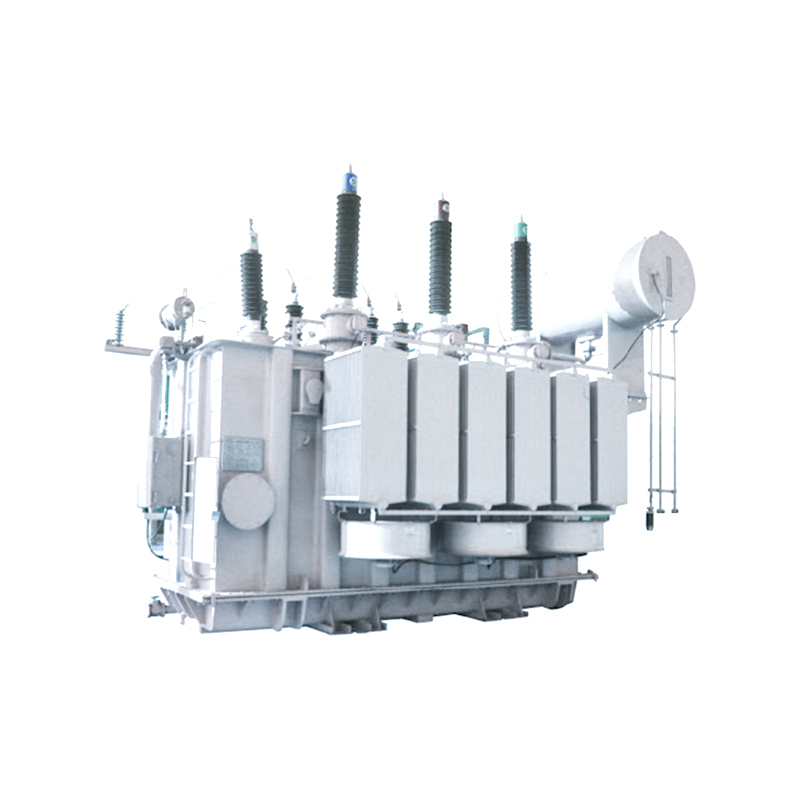

See DetailsThe 110kV ultra-high voltage power transformer is a cornerstone of modern electrical power transmission systems. Operating at voltages of up to 110,000 volts, these transformers enable efficient electricity transport over long distances while minimizing power losses. Designed to handle significant electrical and thermal stresses, they ensure reliability in demanding applications such as power plants, substations, and industrial facilities. Despite their robust construction, one challenge persists: managing inrush currents during switching and energization. These transient currents, if uncontrolled, can cause significant stress on the transformer and the grid, making proper procedures essential for safe operation.

Inrush currents occur primarily due to the magnetization of the transformer core when energized, especially if the residual flux and the applied voltage waveform do not align. These currents can be many times the full-load current, posing risks such as insulation stress, mechanical strain, and potential damage to auxiliary components. To mitigate these risks, a series of deliberate switching and energization procedures must be followed. First, precise planning and pre-energization testing are critical. Operators should measure the residual magnetic flux in the core and align it with the expected flux from the incoming voltage. Modern transformers often incorporate flux monitoring devices to assist with this process, ensuring a smooth transition during energization.

Switching sequence also plays a vital role. Using controlled switching devices, such as synchronized circuit breakers, can significantly reduce inrush currents. These devices are designed to close the breaker contacts at the optimal point on the voltage wave, minimizing the magnetic flux imbalance. Additionally, pre-insertion resistors in circuit breakers can help by momentarily limiting the current surge during the initial energization phase. For older systems without such advanced technologies, energization during periods of light system load can also help to reduce the impact of inrush currents on the grid.

Another effective strategy involves the use of sequential phase energization. Instead of energizing all three phases simultaneously, each phase is energized in a staggered manner. This approach reduces the peak magnitude of inrush currents, distributing the magnetizing process over time. For transformers connected to critical loads or sensitive equipment, operators often deploy current-limiting reactors or surge arresters to shield the system from unexpected spikes. Furthermore, modern transformers are equipped with intelligent monitoring systems that provide real-time feedback, allowing operators to adjust procedures dynamically and mitigate potential issues as they arise.

Proper maintenance and calibration of protective relays are equally crucial. These relays must distinguish between harmless inrush currents and fault currents, ensuring that the transformer is not unnecessarily disconnected from the grid. Advanced digital relays with harmonic restraint features can accurately identify inrush conditions based on the distinctive harmonic content of the current waveform. By combining advanced relay protection with proactive switching practices, operators can significantly enhance the reliability and longevity of the transformer.

In conclusion, the energization of a 110kV ultra-high voltage power transformer is a complex but manageable task, provided the right procedures are in place. By leveraging modern technologies such as synchronized switching, phase-by-phase energization, and intelligent monitoring systems, operators can effectively minimize inrush currents and ensure seamless operation. Beyond technical measures, continuous training and adherence to industry standards are vital in building a resilient power system capable of meeting the demands of today’s electrified world.

Contact Us