Home / Products / Oil Immersed Transformer / Distribution Transformer / Amorphous Alloy Oil-Immersed Three-Phase Transformer

-

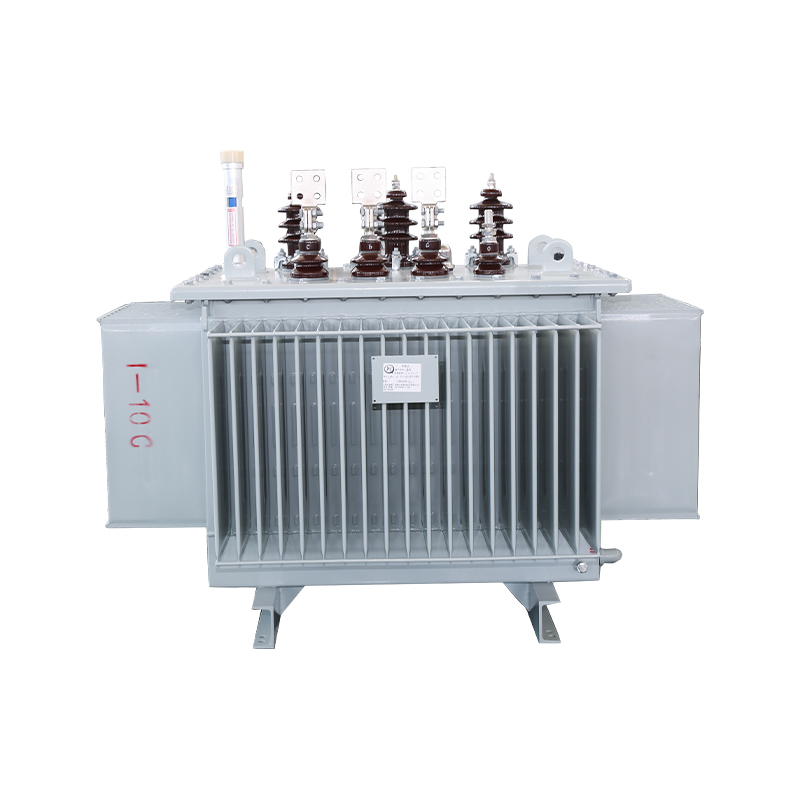

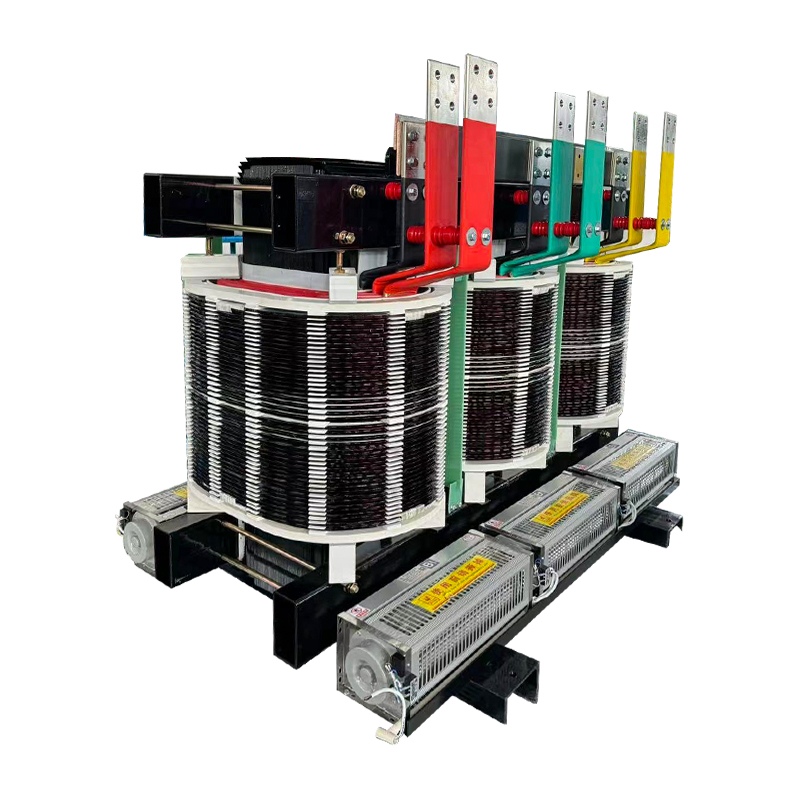

Amorphous alloy oil-immersed three-phase transformer is a power transformer that combines amorphous metal core technology with oil-immersed design. The amorphous structure reduces core losses and makes the transformer more energy efficient. This combination offers several advantages, including greater energy efficiency and reduced energy losses.

-

About Us

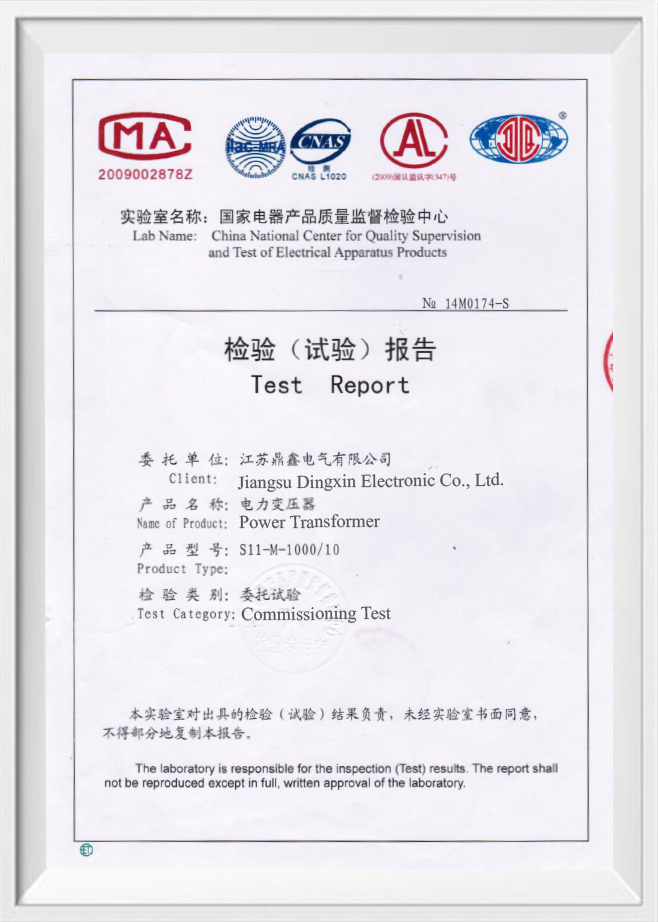

Jiangsu Dingxin Electric Co., Ltd.

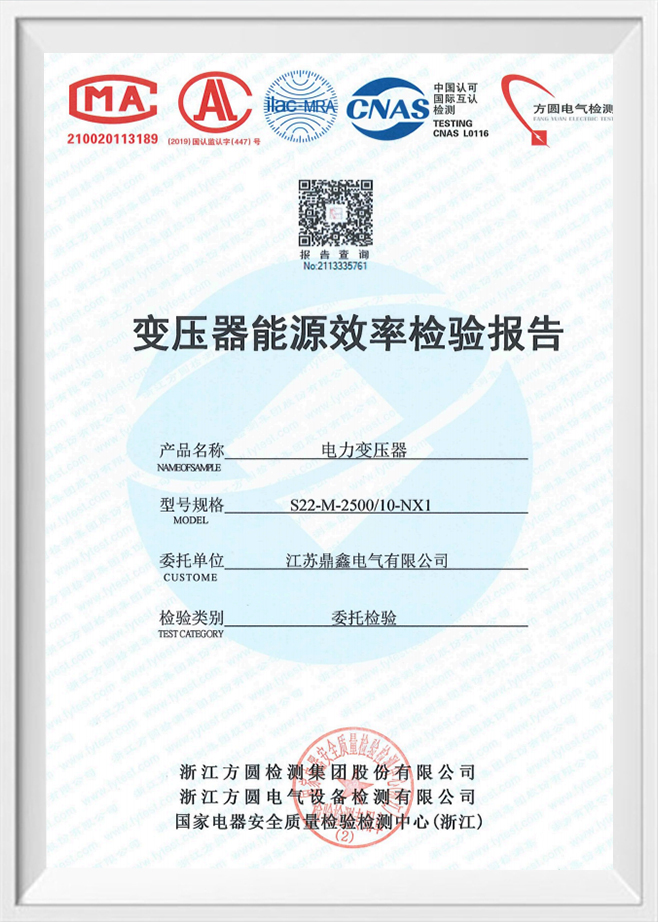

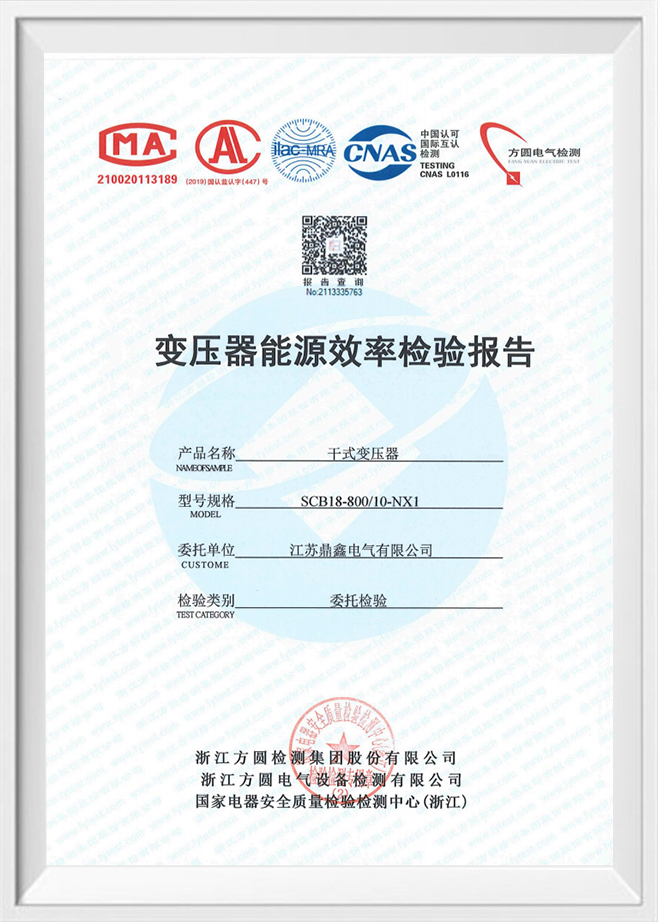

Jiangsu Dingxin Electric Co., Ltd. specialize in the production of power equipment, with an annual production capacity of 50 million KVA. It mainly produces 110KV, 220KV and 500KV ultra-high voltage transformers, various dry-type transformers, oil-immersed transformers, amorphous alloy transformers, wind and solar energy storage transformers, prefabricated substations and reactors of various specifications with voltage levels of 35KV and below. , electric furnace transformer, rectifier transformer, mining transformer, split transformer, phase shift transformer and other special transformer, custom 200KVA 10KV Amorphous Alloy Oil-Immersed Three-Phase Transformer. company have successively passed IS09001, ISO14001, ISO45001, ISO19011 system certification. Among the customers we cooperate with are many urban and rural power grids, as well as petrochemical, metallurgical, textile enterprises, mines, ports, residential communities, etc. We have long-term cooperation with many well-known companies, and we are also qualified suppliers for many listed companies in the electrical industry. In order to achieve high-efficiency production control, we have our own production facility and strictly adhere to procedures like screening and auditing of raw material suppliers, testing of incoming materials, and comparison of incoming materials. Additionally, each batch of products is inspected and quality-controlled in strict accordance with the supplier's indicators. As OEM Low Loss Energy-Saving Three-Phase Oil-Immersed Distribution Transformer Manufacturers and Factory in China, We can more readily satisfy customer demands for minimum order quantities, quality control, delivery times, etc.Product sales cover the national market and are exported to Europe, the United States, Australia, Indonesia, Russia, Africa, Vietnam and other countries.

News

-

Understanding Cast Resin Three-Phase Dry-Type Transformers A cast resi...

READ MORE -

The pad mounted transformer is an integral part of electrical distribu...

READ MORE -

Introduction to Power Transformers and Distribution Transformers In t...

READ MORE -

Understanding switch electrical ratings Every electrical switch is spe...

READ MORE -

Short answer — it depends on the standard and the context Most interna...

READ MORE

Product Industry knowledge

Why does the magnetic core of the 200KVA 10KV Amorphous Alloy Oil-Immersed Three-Phase Transformer use amorphous alloy material?

The selection of materials for the magnetic core is pivotal in determining efficiency and performance. The 200KVA 10KV Amorphous Alloy Oil-Immersed Three-Phase Transformer stands out as a testament to cutting-edge technology, with its magnetic core crafted from amorphous alloy material. This strategic choice is underpinned by several factors that contribute to unparalleled efficiency and sustainability in power distribution.

The selection of materials for the magnetic core is pivotal in determining efficiency and performance. The 200KVA 10KV Amorphous Alloy Oil-Immersed Three-Phase Transformer stands out as a testament to cutting-edge technology, with its magnetic core crafted from amorphous alloy material. This strategic choice is underpinned by several factors that contribute to unparalleled efficiency and sustainability in power distribution.

Reducing Core Losses:

At the heart of the decision to use amorphous alloy lies the quest to minimize core losses. Unlike traditional crystalline alloys, amorphous alloys lack a defined structure, resulting in significantly reduced hysteresis and eddy current losses during the transformer's operation. This translates into lower energy dissipation in the form of heat, making the transformer remarkably efficient in converting electrical power.

Ultra-Low Hysteresis Losses:

Hysteresis losses occur when the magnetic core undergoes repeated cycles of magnetization and demagnetization. Amorphous alloys exhibit ultra-low hysteresis losses due to their disordered atomic structure, allowing them to respond more efficiently to the alternating magnetic fields in the transformer. As a result, the 200KVA 10KV transformer experiences minimal energy losses, ensuring a higher level of energy conservation.

Suppression of Eddy Currents:

Eddy currents, induced by the alternating magnetic field, contribute to energy dissipation within the transformer. The high resistivity of amorphous alloys suppresses the formation of eddy currents, further diminishing energy losses. This characteristic makes the amorphous alloy an ideal choice for applications where the reduction of electromagnetic losses is paramount.

Environmental Considerations:

Beyond its performance benefits, the use of amorphous alloy aligns with contemporary environmental sustainability goals. The manufacturing process of amorphous alloys typically requires less energy compared to traditional crystalline alloys. This reduction in energy consumption during production, coupled with the transformer's heightened efficiency during operation, contributes to an overall decrease in the carbon footprint.

Enhanced Transformer Lifespan:

The unique properties of amorphous alloys not only improve efficiency but also contribute to the longevity of the transformer. The reduced heat generated by lower core losses ensures that the transformer operates within optimal temperature ranges, preventing accelerated aging and enhancing overall reliability.

The utilization of amorphous alloy material in the magnetic core of the 200KVA 10KV Transformer is a strategic engineering choice aimed at achieving unparalleled efficiency and sustainability. As the energy industry continues to prioritize resource efficiency and environmental consciousness, transformers incorporating amorphous alloys set a benchmark for the future of power distribution technology, demonstrating that material innovation is key to meeting the evolving needs of our electrified world.

Is the energy loss during operation of Amorphous Alloy Oil-Immersed Three-Phase Transformer lower?

In the pursuit of sustainable and energy-efficient power distribution, the Amorphous Alloy Oil-Immersed Three-Phase Transformer has emerged as a game-changer, promising to redefine the benchmarks for efficiency in the realm of transformers. The question at the forefront is whether the energy loss during the operation of New Energy Low Loss Energy-Saving Three-Phase Oil-Immersed Distribution Transformer is indeed lower compared to traditional counterparts.

The Amorphous Advantage:

At the heart of the efficiency revolution in these transformers is the use of amorphous alloy material for the magnetic core. Unlike conventional crystalline alloys, amorphous alloys possess a disordered atomic structure, which significantly reduces core losses during operation. This property directly translates into lower energy loss, making amorphous alloy transformers highly sought after for their superior energy efficiency.

Hysteresis Losses Minimized:

Hysteresis losses, a significant contributor to energy dissipation in transformers, are notably diminished in Amorphous Alloy Oil-Immersed Three-Phase Transformers. The disordered molecular structure of amorphous alloys allows them to respond more efficiently to the alternating magnetic fields, leading to ultra-low hysteresis losses. This characteristic ensures that a greater proportion of the input electrical power is efficiently converted and delivered to the end-user.

Suppression of Eddy Currents:

Eddy currents, induced by the alternating magnetic field in the transformer, contribute to additional energy losses. Amorphous alloys, with their high resistivity, effectively suppress the formation of eddy currents, further mitigating energy dissipation. This dual reduction in hysteresis and eddy current losses sets amorphous alloy transformers apart, offering a compelling solution for minimizing energy waste in power distribution systems.

Real-World Applications:

The effectiveness of Amorphous Alloy Oil-Immersed Three-Phase Transformers in reducing energy loss has been validated in real-world applications. Various studies and field tests have demonstrated that these transformers consistently outperform traditional counterparts in terms of efficiency, leading to tangible energy savings. This empirical evidence substantiates the claim that the energy loss during operation is indeed lower in amorphous alloy transformers.Environmental and Economic Implications:

Beyond the immediate energy savings, the lower energy loss in amorphous alloy transformers carries significant environmental and economic implications. Reduced energy dissipation results in lower greenhouse gas emissions, aligning with global efforts to mitigate climate change. Additionally, the economic benefits stemming from lower energy consumption contribute to the overall cost-effectiveness and sustainability of power distribution networks.

The energy loss during the operation of Amorphous Alloy Oil-Immersed Three-Phase Transformers is unequivocally lower compared to traditional transformers. The transformative impact of amorphous alloy technology not only enhances efficiency but also aligns with the broader goals of sustainability and responsible energy consumption. As the world pivots towards greener energy solutions, these transformers stand as a beacon of innovation, showcasing that a small change in material composition can yield substantial gains in energy efficiency and environmental conservation.

English

English русский

русский Español

Español