Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer

15KVA 13.8KV/0.4KV

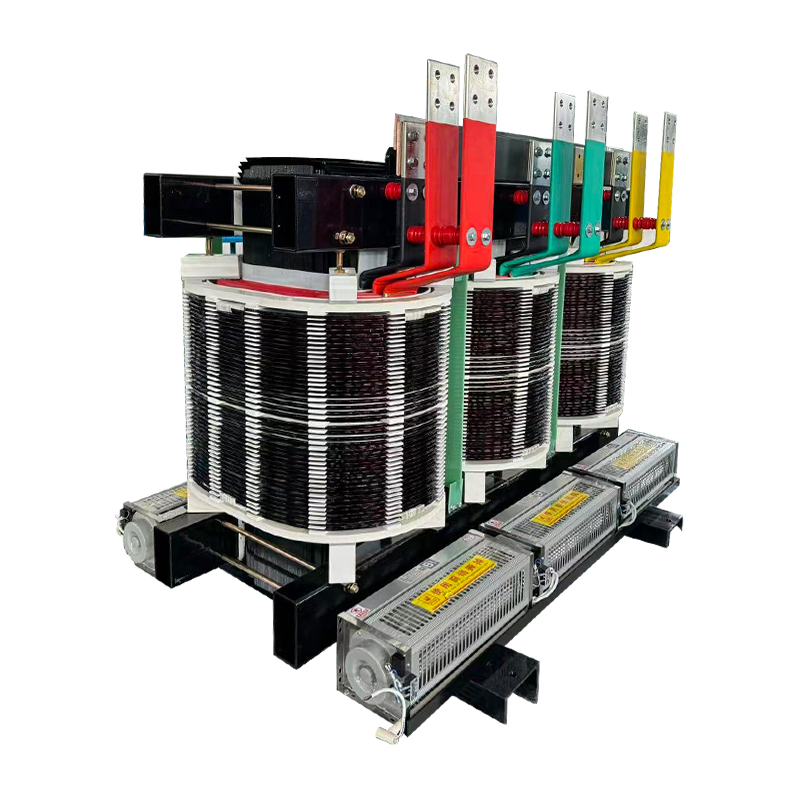

See DetailsNon-encapsulated insulated dry-type transformers are integral components in modern power systems, known for their energy efficiency, reliability, and environmentally friendly design. Among the key innovations that have enhanced their performance is the use of polymer-based insulation material, which has brought significant improvements in various operational aspects. This material's contribution to transformer durability, heat management, and compliance with international safety standards has made it an essential feature in heavy-load applications across industries such as manufacturing, infrastructure, and power distribution.

The polymer-based insulation material used in non-encapsulated transformers plays a vital role in optimizing the transformer’s ability to withstand high temperatures, which is crucial in heavy-load applications. Transformers naturally generate heat during operation, especially when dealing with large power demands, and the ability to dissipate this heat effectively is critical for preventing overheating and ensuring consistent performance. The polymer insulation excels at this, as it not only tolerates high temperatures but also promotes efficient heat dissipation. This ensures that the transformer operates within safe temperature limits, reducing the risk of thermal degradation and prolonging the equipment's operational life.

Another major benefit of polymer-based insulation is its contribution to the transformer’s electrical performance. The material has excellent dielectric properties, which means it can effectively resist electrical breakdown under high voltage stress. This is crucial in non-encapsulated designs, where the insulation must maintain strong performance even in the absence of a solid, encapsulating material. By enhancing the electrical integrity of the transformer, polymer insulation helps prevent failures that could lead to power interruptions or safety hazards, thus improving the overall reliability of power systems where these transformers are installed.

Durability is another significant advantage provided by polymer insulation. Traditional insulation materials can deteriorate over time due to exposure to environmental factors such as moisture, dust, or chemicals, but polymer-based materials are far more resistant to these influences. This makes non-encapsulated transformers suitable for both indoor and outdoor installations, even in harsh environments. The improved resilience of the insulation reduces the need for frequent maintenance and replacements, which translates into long-term cost savings for operators, particularly in industrial or utility settings where downtime can be costly. The robust nature of polymer insulation also helps these transformers meet stringent international safety and performance standards, ensuring that they are reliable and safe to use across various global markets.

Furthermore, Non-encapsulated insulated dry-type transformers with polymer insulation are inherently more sustainable and energy-efficient. The insulation's thermal stability allows the transformer to run more efficiently under heavy loads, reducing energy losses and contributing to overall energy savings in power distribution systems. This aligns with the growing emphasis on environmental protection, as industries and governments strive to minimize carbon footprints. In fact, the design of these transformers, which forgoes oil or other liquid cooling systems, adds to their eco-friendly profile, as they do not present the same risk of environmental contamination in the event of leaks or failures. The insulation material itself also complies with modern environmental regulations, further reinforcing its role in sustainable power infrastructure.

Contact Us