Metal Enclosed High Voltage Switch Cabinet

KYN28

See Details

A Cabinet-Type Outdoor Prefabricated Substation, which is a compact, all-in-one electrical distribution solution designed for outdoor installation. Th...

See Details

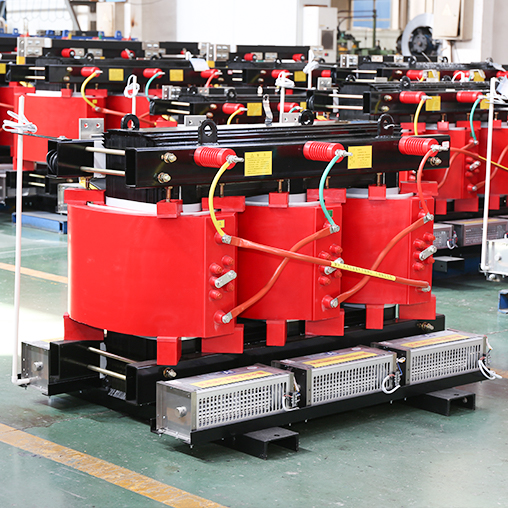

Base kVA: 45 kVA to 12,000 kVA Primary voltage: 2400 V to 46,000 V Secondary voltage: 120 V to 24,940V Basic lmpulse Level (BIL): 30kV to 250kV

See Details

A Cabinet-Type Outdoor Prefabricated Substation, which is a compact, all-in-one electrical distribution solution designed for outdoor installation. Th...

See Details

Base kVA: 45 kVA to 12,000 kVA Primary voltage: 2400 V to 46,000 V Secondary voltage: 120 V to 24,940V Basic lmpulse Level (BIL): 30kV to 250kV

See Details

A Cabinet-Type Outdoor Prefabricated Substation, which is a compact, all-in-one electrical distribution solution designed for outdoor installation. Th...

See Details

Base kVA: 45 kVA to 12,000 kVA Primary voltage: 2400 V to 46,000 V Secondary voltage: 120 V to 24,940V Basic lmpulse Level (BIL): 30kV to 250kV

See DetailsCopyright © Jiangsu Dingxin Electric Co., Ltd. Rights Reserved.

Energy Efficient Transformers Manufacturers Electrical Transformers Factory

Contact Us